13

2022

-

06

How to judge the age of the linen before picking up the customer's linen and avoid being a "back-pot man"?

Author:

Testing is not only to confirm the performance of the final product, but also to escort the quality and reputation through the control process; not only can problems be found and corrected in time, but also can be prevented in advance by analyzing trends; not only to obtain stable and reliable product output, but also It is to reduce unnecessary cost waste, gain customer trust through standardized behavior, and ultimately improve competitiveness and increase revenue.

Of course, quality is first produced, not detected. Only when every link in the production process is carried out in strict accordance with the process and process requirements, can the final product quality be guaranteed. Therefore, quality control is a systematic process, and inspection is an important part of quality control. Through detection improvement and optimization management, the ultimate goal is to meet policies and regulations, technical requirements and customer satisfaction. Detection, inspection and inspection have different meanings. In simple terms, inspection has data; inspection is mainly for verification, such as appearance; inspection does not produce data, such as operation, process verification, etc. The detection we are discussing today covers all three of the above. From the incoming of raw materials to the outgoing of finished products, the links that need to be tested include raw materials, processes and finished products. Laundry factories can be regarded as a special kind of production enterprises. Here, soiled fabrics or fabrics to be washed, washing chemicals and washing media are the raw materials and the washing environment; the process conditions are the process; the cleaning fabrics and services are the products; and the generated environmental wastes are by-products.

Inspection of raw materials

1.1 New linen

Because the textile production industry is relatively standardized, the standards are relatively comprehensive, and the technical indicators are clear and clear, the detection of new linen is still very easy to operate. We can select the indicators related to us for testing according to the standard requirements of different categories and different levels. For example, color fastness, breaking strength, tear strength, yarn count, shrinkage, linear density, gram weight, etc. to evaluate the quality of new products. The quality of textiles on the market is mixed, and there are indeed many products that cannot meet the quality requirements of national recommended standards or even mandatory standards. If the relevant testing and confirmation are not carried out before being put into use, there may be quality problems of the washed product due to the unqualified quality of the linen itself during the washing process. Once the fabric has been washed, it cannot be tested and judged according to the standards of new products. As far as the current situation is concerned, some washing plants may not have considered this step. If this is the case, we recommend that the product sample work be done in a formal way. If there is a problem, you can send the sample product for inspection to recover the loss.

1.2 Old linen

The situation with old linen is more complicated. In view of the lag in the development of the washing industry compared with other industries, under the current conditions, not only domestic but also foreign countries have basically failed to effectively evaluate the quality of old linen received by washing plants. In addition, due to the particularity of industrial laundry, its technical requirements are different from those of civilian laundry. Industrial washing is mechanical washing, operated by professionals. Early industrial detergents usually used chemical raw materials such as strong alkali, strong acid, strong oxidant and strong reducing agent, so as to ensure a strong washing effect. In addition, the current domestic standards mainly require the fabrics after washing in terms of hygiene and cleanliness, while the residual chemical substances and the degree of fiber damage are difficult to visually detect and characterize, and there is also a lack of standard requirements.

At present, both detergent manufacturers and washing companies have problems such as large number, small scale, scattered irregularities and so on. In order to increase the pass rate of washing or reduce costs, some companies will choose to adopt chemical violence methods, strengthen acids, strong alkalis and a large amount of bleaching agents. Although ensuring that the final pH value meets the standard, hygiene and whiteness requirements, it comes at the cost of sacrificing the life of the linen and neglecting the health of the user. What's more, because of the disputes with the hotel, when the laundry factory is changed, the linen is violently washed, and the next laundry factory will become a "pot man".

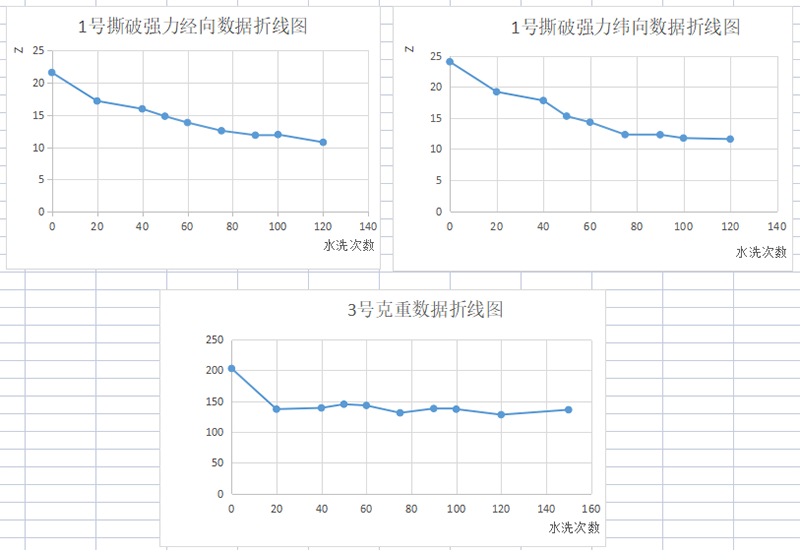

To sum up, in this case, what is the state of the linen we receive is actually very important. Although we do not have clear criteria for judging the condition of old linen, it is necessary to conduct a simple evaluation of this linen. We can at least detect whether it already contains fibers seriously weakened by strong acid and alkali, so as to avoid damage when we put it into washing for the first time or later; we can also detect its approximate lifespan. From the perspective of normal process washing, it can be Roughly what "age" has been reached. All of these tests, Just (Beijing) Testing Co., Ltd., can help you.

嘉思特床单水洗数据库部分数据

1.3 Washing chemicals

The two most important aspects of cleaning chemicals, one is the active ingredient, and the other is the effectiveness. The active ingredients of detergents are the guarantee that stains can be effectively removed, and the active ingredients are relatively expensive in the formulation of detergents. In order to save costs, most detergent manufacturers will not add more than the standard requirements, and even many non-standard detergent manufacturers will replace the active substances of their products with other fillers with shoddy ones, which cannot meet the product standard requirements at all. , causing the laundry factory to suffer a dark loss, need to increase the dosage to wash the linen well, or sacrifice the washing quality without increasing the amount of detergent. The effectiveness of cleaning chemicals, such as our bleaching agents, are all oxidants, that is, chemical materials with active chemical properties. They have special requirements for storage conditions, and their shelf life is much shorter than conventional detergents. If we do not carry out incoming inspection, storage control, and random testing during use, the laundry factory is very likely to use chemicals that fail or whose efficiency drops a lot. The consequences of this situation, one is that the expected bleaching effect is not achieved, and the other is that the quality of hygiene will also be affected. Of course, some important properties of other chemicals will also have a great impact on our washing quality, such as the poor water absorption of fabrics caused by some unqualified properties of softeners.

1.4 Washing water

The importance of washing water is well known. Poor water quality will cause the linen to turn gray, yellow, dark, and hard, reducing the detergent effect and blocking the pipeline. The adverse effects of washing water on linen are mainly considered from two aspects. The above problems are caused by unqualified physical and chemical properties, such as hardness, iron, manganese, and copper exceeding the standard; the other is the microbial aspect. If the microbial content of the washing water itself exceeds the standard, Then it is difficult for us to meet the standard of hygiene testing of clean fabrics after washing. For the quality inspection of washing water, the physical and chemical indicators are recommended to follow the "Quality Requirements for Cleaning of Textiles for Public Use" (GB/T 35744-2017), and the hygiene indicators can refer to the requirements of "Technical Specifications for Washing and Disinfection of Medical Fabrics in Hospitals" (WS/T508-2016) .

Process control

2.1 Process control

Process control includes control of temperature, time, mechanical force and concentration of washing liquid during the washing process. If the temperature and action time fail to meet the requirements, it will not only affect the cleanliness effect of washing, but even cause the invisible microorganisms to exceed the standard and environmental pollution. Problems with mechanical force may be directly reflected in the washing effect of linen. For temperature, time and mechanical force, we need institutionalized standard operating procedures (SOP) for inspection and maintenance, and the detection of active ingredients can now also use rapid test methods provided by some large detergent manufacturers.

2.2 Environmental Control

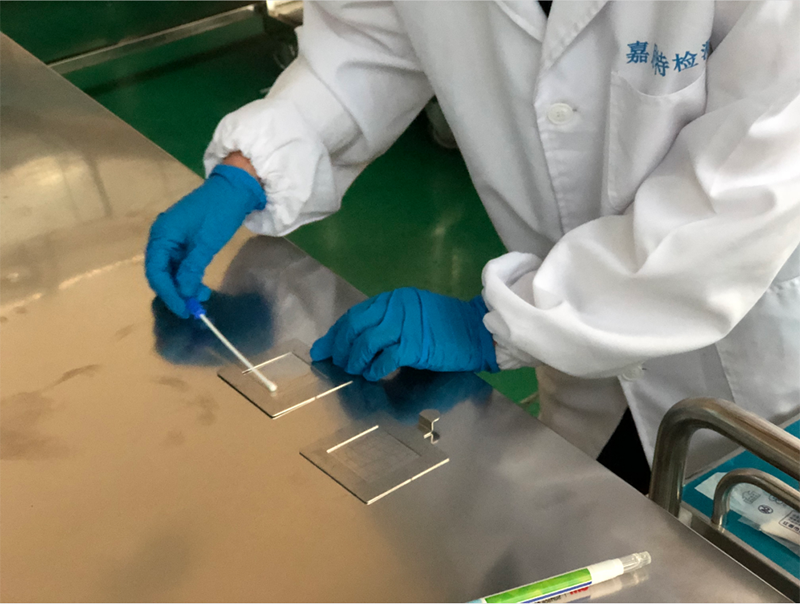

Environmental pollution will lead to poor quality of fabric hygiene, so it is necessary to properly disinfect the environment on a regular basis. We once solved the problem of substandard production quality for a laundry factory. We have been cooperating with this laundry factory for linen testing. Once, we found that their total bacterial colony of linen after washing was seriously exceeding the standard, and we took the initiative to assist in finding the cause. We first tested the staff's hands, air, hard surfaces, etc., and found that not only the microorganisms of the linen were seriously exceeding the standard, but the environment was also severely polluted. meet the process requirements. Analysis and judgment should have been in this situation for a period of time, or it may be that the microbial contamination of dirty linen was serious and caused the pollution of the production line. Although the customer immediately corrected the washing process and the use of chemical disinfectants, the hygienic quality was gradually restored to an acceptable level after several washings. Therefore, we can see from this that once there is a problem with the hygiene indicators, we should not only focus on the washing process itself, but also on the cleaning and disinfection of the washing environment. We later provided training on environmental disinfection for this customer, and also helped the customer set up a physical and chemical quality inspection room, and helped them do environmental monitoring and fabric hygiene testing after disinfection in a cooperative preferential way, which provided the standard for their washing quality. Effective protection.

Product testing

3.1 Cleaning fabrics

The inspection of cleaning fabrics is generally completed according to the requirements of customers or the requirements of standard specifications. In fact, as a washing enterprise itself, regular quality inspection of cleaning fabrics and statistical analysis, early prevention, and risk prediction are also of great benefit to the overall quality control and word-of-mouth improvement.

3.2 Wastewater discharge

In today's global situation, no matter what we do, we cannot destroy our living environment. Even from the perspective of environmental inspections, the daily testing of wastewater discharge indicators is also very important. In fact, in most cases, we do not need to obtain accurate results like third-party testing agencies. Washing wastewater mainly refers to the wastewater generated by washing clothes by washing machines. Insoluble impurities, etc. For common indicators in the washing industry, such as COD, total phosphorus, total nitrogen, pH, etc., we can take a rapid detection method or a preliminary judgment method to understand. In this regard, if necessary, you can contact Garst. Tel: 176 0099 1712

Article source: Reprinted from the December 2021 issue of "Chinese and Foreign Laundry".